Turbocharged engines are becoming commonplace as the vehicle manufacturers are utilizing smaller displacement engines fitted with turbochargers. Turbochargers and direct fuel injection can make a smaller displacement engine behave like a larger displacement engine, while accomplishing better fuel economy. With this technology comes some challenges, especially in the area of required maintenance. Failure to provide the needed services can result in some major expensive repairs.

Most maintenance recommendations focus on lubrication concerns such as oil and fi lter service intervals based on normal or severe service conditions. The primary focus has been on the protection of the internal engine components. While this is an important concern, little focus has been placed on the effects of turbocharger failure due to improper service intervals or operating procedures.

Turbocharger failures are usually the result of lack of maintenance, poor lubrication due to contamination and foreign objects being introduced via the airway. Improper engine startups and shutdowns often result in bearing failures and shaft seizures due to lack of lubrication during these critical stages of vehicle operation. Turbochargers operate under extreme pressure and temperature from the hot exhaust that can approach 2000 degrees F, often in a speed range exceeding 200K RPMs. Cold driveaway or hot engine shutdowns can result in bearing failure and shaft seizure due to absence of lubrication during these critical engine startups and shutdowns.

Vehicles driven beyond the recommended service interval may encounter heavy deposits that can restrict lubricant flow through the turbocharger, resulting in bearing failure. Contaminated oil has been a leading cause of turbocharger failures. Poor lubrication can promote bearing or shaft wear, or in some cases shaft breakage. When this occurs the turbine or compressor may contact the turbocharger housing, causing parts to bend or break due to the radial movement of the shaft. Contamination in the lubricant usually consists of minute carbon deposits resulting from the combustion process. The deposits are abrasive, resulting in clearance issues and plugging within the oil feed tubes/galleries. When lube services are not performed at the proper service interval, gelling and the formation of sludge results in clogged oil passages. The turbocharger requires the same clean lubricant as the engine for protection of its internal components. Further, the correct oil viscosity is imperative for providing proper lubrication and coolant for the turbocharger.

The physical size of the filter does not determine the efficiency of the fi lter. Filters with the same dimensions may be constructed with a different filtration media or number of the pleats, which affects the efficiency of the filter. A smaller design filter may have a higher efficiency rating when compared to a larger design filter.

Turbochargers need clean air. A restricted or damaged air filter can create performance issues or lead to the failure of the turbocharger. The purpose of the air filter is to protect the engine from contaminants such as bugs, dust, dirt, and other sorts of debris. In turbocharged applications, major damage can occur when one of the mentioned contaminants makes contact with the compressor side of the turbo that can be spinning at 200K RPMs or greater. Any foreign object making contact with the compressor at this speed can result in some major expensive damage. It creates the same syndrome as throwing a stick in the bicycle spokes, resulting in bent and broken parts.

While performing an air filter inspection is a key part of the maintenance inspection, make certain that you examine the integrity of the filter housing and related plumbing. Damage to the housing, air box or hold-down clamps can result in a catastrophic engine or turbocharger failure. Plastic, rubber and metal components fail, allowing unfiltered air and debris to enter the engine. Pay special attention to the clean air side of the air box and related housings for evidence of dirt or dust, which is an indication of filter by-pass. Examine the filter seal for evidence of dust trails across the seal, which would be an indication of a damaged air box or missing or broken clamps. Turbo-Diesel applications often encounter a condition referred to as dusting, whereby contamination such as dust or dirt is actually pulled through the filter media.

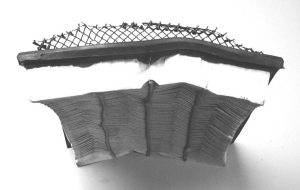

Pay special attention for evidence of water or snow contamination, which can cause major performance issues and costly engine or turbocharger damage. The illustration below reflects a filter that was pulled from the air box when subjected to road splash, which resulted in a hydro-lock condition.

Turbocharger failure is usually the result of poor lubrication or the introduction of foreign objects entering the compressor housing by way of the air filter or housing. The debris can be external or internal. Foreign objects that result in turbine or compressor damage can also come from the engine. For example, a failed engine component can pass through an intake or exhaust valve resulting in major turbocharger damage. Fine particles of carbon from the combustion process results in erosion of the turbocharger bearings and shaft, resulting in clearance issues or restriction in the oil galleries that lubricate the shaft. Let’s consider additional causes of turbo failure:

1) Lengthy engine idling can create a low-pressure condition in the turbo housing, promoting a vacuum condition, which results in oil leaking into the turbine housing.

2) Hard acceleration during cold engine operation promotes lack of lubrication and wear on the bearings and shaft.

3) Immediately shutting down a hot engine promotes carbon build-up in the turbo.

4) Prior to shutting down a hot engine it should be idled for a few minutes to allow the turbo speed to slow down and dissipate the heat. Immediately shutting down the engine results in no lubrication for the turbo during this coast down period, promoting wear to the shaft, bearings and seals.

5) Improper service intervals can result in blockage in an oil return pipe, promoting oil leaks from the compressor and turbine.

6) Overfilling the crankcase during a service can cause a pressure build-up in the bearing housing or oil being forced back up the return pipe causing leakage.

7) Blow-by gases in the crankcase causes an over pressurization affecting oil flow to the turbo.

1) Power loss

2) Turbo lag

3) Loud noise on acceleration

4) Excessive exhaust smoke due to damaged seals or cracked housing from intense heat

5) Difficulty maintaining highway speeds

TO EXTEND TURBOCHARGER LIFE

1) Regular scheduled maintenance

2) Recommended lube service intervals

3) Vehicle manufacturer’s recommended oil viscosity

4) Following proper start-up and shut-down procedures necessary to provide sufficient lubrication and cooling

5) Clean air filter and sealed air box

View PDF

This is extremely valuable information to have because seeing more engine failures especially with turbo engines.

Thank you, Ron!