Nothing is more frustrating for the vehicle owner than a puddle of oil on their carport floor or the stench of oil on a hot engine or exhaust system following a lube service. It is equally frustrating for the lube shop as they must correct the problem, losing billable labor time.

We have seen customers return following a lube service with an oil leakage complaint and the lube technician installing a second or third oil filter in a futile attempt to correct the leakage complaint. It is unlikely that you will encounter multiple oil filter failures, consecutively. Failure to accurately diagnose the cause of the leakage can result in the customer losing confidence in the shop’s ability to properly service their vehicle, and you will likely lose a customer in the process.

If evidence of oil leakage is present prior to performing the lube service, the customer should be made aware of the condition and documentation should be made on the repair order. Often, the technician gets blamed for a condition that may have been inherent in the vehicle prior to the lube service. This article will illustrate some sources of potential leakage that should be considered when diagnosing leakage complaints. When leakage complaints involve applications that are fitted with oil coolers, special attention must be given to those components and related gaskets/O-rings.

Chrysler, Dodge and Jeep applications equipped with 2.0L and 2.4L engines may encounter oil cooler leakage that may be misdiagnosed as oil filter leakage. These applications call for the M48 series filter. A clean-up of the area will be the first step required to pinpoint the source of the leak.

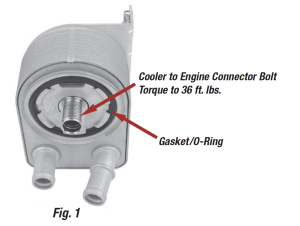

The engine side of the oil cooler is sealed to the engine with a gasket/O-ring secured by a connector bolt. The opposite end of this bolt also serves as the oil filter attachment point. The bolt should be torqued to 36 ft. lbs. (see Fig.1). It is possible for the connector bolt to loosen in the process of multiple oil filter changes, resulting in leakage. Eventual gasket compression can also occur, requiring a replacement gasket between the cooler and engine.

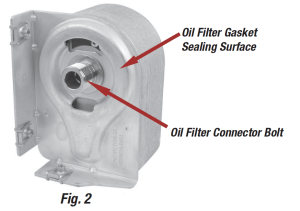

The oil filter side of the oil cooler (see Fig. 2) should be inspected for damage or deformation that could prevent the oil filter gasket from sealing properly to the cooler. The cooler is a stamped piece of metal and not a machined surface like the engine block. Overtightening the connector bolt can result in damage or distortion to the cooler. A bolt that is not properly torqued can loosen when performing oil filter changes, especially if the oil filter was previously overtightened.

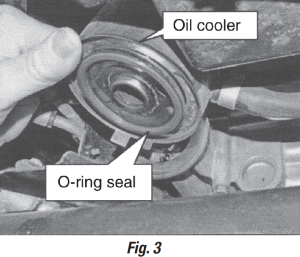

Oil cooler leakage has plagued Nissan applications equipped with VQ30 (3.0L) and VQ35 (3.5L) engines since the year 2000. The same oil cooler arrangement is included with current production vehicles. These applications call for the M4612 series filter, which has been mistakenly blamed for the oil leakage. The leakage occurs due to a poor seal between the oil cooler O-ring and the engine. Nissan has a revised O-ring for the oil cooler, which is not a typical O-ring, requiring a trip to the dealer (see Fig. 3).

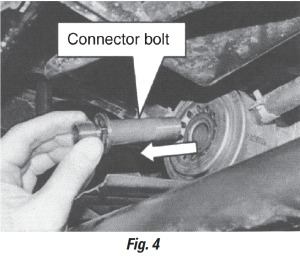

Nissan recalled certain production vehicles including: 2011- 2012 Nissan Frontier, Xterra, Pathfinder and Nissan NV vehicles. Some of the connector bolts that secure the oil cooler to the engine were manufactured below specification strength. The bolts may break at the oil filter attachment point resulting in leakage (see Fig. 4). The torque spec for the connector bolt is 36 ft. lbs.

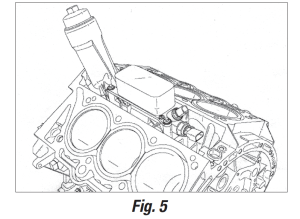

Filter housing and cooler leakage has plagued Chrysler’s 3.6L Pentastar engine. The plastic housing and cooler assembly is positioned beneath the intake manifold between the cylinders (see Fig. 5). This area may accumulate a quart of oil before displaying any sign of a leakage. This may prevent the technician from observing any leakage following the lube service. When changing the oil filter, the cap should not be over tightened. The cap is stamped with a torque spec of 25 Nm (18 ft. lbs.). Overtightening can damage the cooler housing in the form of cracks or disturbing the housing O-rings, promoting oil or coolant leakage.

It makes good business to check for oil pooling beneath the intake (engine valley) on any application fitted with the same oil filter/cooler arrangement prior to performing a lube service. Performing this service may prevent you from having to absorb some unnecessary parts and labor costs.

To check for oil pooling in the engine valley, fabricate a dipstick (preferably of wood) and insert it next to the oil filter housing, and allow it to bottom out in the engine valley.

If oil is pooling in this area, the oil filter/cooler housing will most likely require replacement. A small amount of oil (wetness) on the tip of the fabricated dip stick may be the result of spillage when changing the oil filter and should be no cause of concern.

The presence of oil pooling in this area calls for an immediate discussion with the vehicle owner prior to performing a lube service. If the customer is not receptive to having the housing replaced, make certain you document your recommendation on the repair order and retain a copy. We have read reports of vehicles encountering fires due to oil leakage from the oil filter housing. For additional information and illustrations, refer to Tech Tip 180 Chrysler’s 3.6L Pentastar Engine.

View PDF

Leave a Reply